The Rising Demand for Lunch Box Molds and Plastic Fork Molds in the Food Packaging Industry

The food packaging industry is witnessing a growing reliance on lunch box molds and plastic fork molds as manufacturers strive to meet the increasing demand for high-quality and cost-effective products. These molds play a pivotal role in shaping the future of food packaging, enabling efficient production and innovation. Let's explore why lunch box molds and plastic fork molds are gaining popularity and how they address the challenges of modern manufacturing.

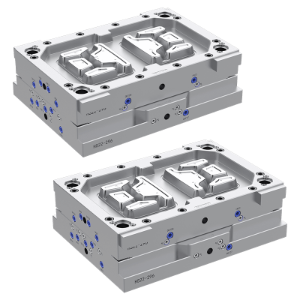

Disposable Plastic Square Three Grid Box & Lid Thin Mould

1. Why Lunch Box Molds Are Essential in Food Packaging

Lunch box molds are specially designed to create durable, reusable, and eco-friendly lunch boxes. The rise in consumer preference for sustainable and reusable packaging has driven the demand for lunch box molds. Manufacturers are now using advanced materials and precision techniques to ensure that each mold produces boxes that meet food safety and durability standards.

Additionally, lunch box molds support mass production while maintaining consistent quality. Whether it's for school, office, or travel use, the demand for lunch boxes remains steady, making lunch box molds an indispensable tool in the packaging industry.

2. The Role of Plastic Fork Molds in Disposable Cutlery Production

Plastic fork molds are at the heart of producing lightweight, cost-effective disposable cutlery. These molds enable manufacturers to create forks that are not only functional but also aesthetically pleasing. With the rise of food delivery services and on-the-go dining, the need for disposable forks has skyrocketed.

Furthermore, plastic fork molds allow for customization, enabling businesses to create branded or uniquely designed cutlery. This capability helps businesses stand out in a competitive market while catering to specific customer needs.

3. Trends Driving the Popularity of Lunch Box and Plastic Fork Molds

Several market trends are contributing to the rising demand for lunch box molds and plastic fork molds:

Sustainability: Consumers are increasingly looking for eco-friendly options. Manufacturers are adapting by using molds that support the production of biodegradable or recyclable materials.

Customization: Businesses are seeking molds that allow for unique shapes, sizes, and branding opportunities.

Mass Production: As the food packaging industry grows, manufacturers need molds capable of high-speed, high-volume production.

Both lunch box molds and plastic fork molds are evolving to meet these demands, incorporating advanced materials and innovative designs to improve efficiency and reduce waste.

4. Benefits of Investing in High-Quality Molds

Investing in reliable lunch box molds and plastic fork molds offers several advantages for manufacturers:

Cost Efficiency: High-quality molds reduce material waste and minimize production downtime.

Durability: Molds made from robust materials ensure a longer lifespan, reducing replacement costs.

Precision: Advanced molds produce items with consistent quality, ensuring customer satisfaction.

For businesses in the food packaging industry, choosing the right lunch box molds and plastic fork molds can lead to improved productivity and profitability.

5. Future Outlook: The Role of Innovation in Mold Manufacturing

The future of lunch box molds and plastic fork molds lies in continued innovation. As technology advances, molds will become even more efficient, enabling the production of smarter, more sustainable packaging solutions. Manufacturers who embrace these innovations will be well-positioned to meet the growing demands of the food packaging market.

The rising demand for lunch box molds and plastic fork molds reflects the evolving needs of the food packaging industry. By enabling efficient, sustainable, and customizable production, these molds are shaping the future of packaging. As consumer preferences shift and industry standards rise, the importance of investing in high-quality molds will only continue to grow.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français