Custom Plastic Moulds: How Disposable Plastic Round Food Container Moulds and Plastic Cup Moulds Can Be Tailored for Specific Needs

Custom plastic moulds have become essential for various industries, particularly in the production of disposable plastic round food container moulds and plastic cup moulds. These tailored moulds ensure that manufacturers meet specific requirements for product design, durability, and efficiency. In this article, we will explore how these custom moulds are made and why they are crucial in meeting specific industry needs.

The Need for Custom Plastic Moulds

In today's fast-paced manufacturing world, industries need to produce products that are both cost-effective and efficient. Disposable plastic round food container moulds and plastic cup moulds are no exception. These moulds play a vital role in the foodservice, packaging, and beverage industries, where bulk production with precision is essential. Custom plastic moulds are specifically designed to meet the unique specifications of these products, ensuring better fit, function, and quality control.

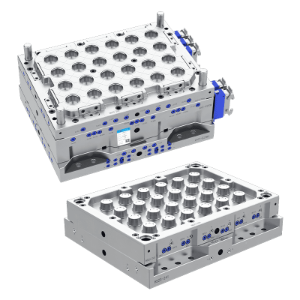

Disposable Plastic Split-type Sauce Cup Mold

Benefits of Custom Plastic Moulds

Enhanced Product Design Flexibility

One of the primary advantages of custom plastic moulds is the flexibility they provide in design. Manufacturers can create a range of designs that cater to the specific needs of their business. For instance, custom plastic cup moulds allow businesses to design cups in different shapes, sizes, and features that suit their branding and product requirements. Similarly, disposable plastic round food container moulds can be tailored to create containers that are both functional and visually appealing, enhancing the overall customer experience.

Improved Durability

Custom moulds are made using high-quality materials designed to withstand the rigors of mass production. This is especially important for industries such as food packaging, where safety and durability are paramount. By using custom-made plastic cup moulds, manufacturers ensure that the final product is not only strong but also resistant to wear and tear during the production process.

Optimized Production Efficiency

Custom plastic moulds are designed to meet the specific needs of manufacturers, which helps improve production efficiency. For example, a well-designed disposable plastic round food container mould can reduce cycle times and increase the output of containers. This leads to lower production costs and faster delivery times, which are crucial in industries where time is money.

Cost-Effectiveness

While custom plastic moulds may require a higher initial investment, they offer long-term savings. Custom-made moulds are built to last longer and perform better, reducing the need for frequent replacements or repairs. This is particularly important in high-volume production environments like food packaging, where downtime due to equipment failure can lead to significant losses. By investing in high-quality custom plastic moulds, manufacturers can ensure consistent performance and better profitability over time.

Customization for Industry-Specific Needs

Disposable plastic round food container moulds and plastic cup moulds are often designed with specific features tailored to the needs of the foodservice and beverage industries. For example, food container moulds can be customized to create containers with compartments or specific lid designs, depending on the type of food being packaged. Similarly, plastic cup moulds can be adjusted to create cups with special features, such as thicker walls for insulation or unique textures for better grip.

Meeting Environmental Standards

Custom moulds also play a significant role in meeting environmental regulations and sustainability goals. With growing concerns about plastic waste and the need for more sustainable products, manufacturers can design plastic moulds that are optimized for recycling or that use eco-friendly materials. Plastic cup moulds can be designed to use less plastic while maintaining strength and functionality, helping businesses meet consumer demand for more sustainable products.

How Custom Plastic Moulds Are Made

The process of creating custom plastic moulds begins with the design phase. Manufacturers collaborate with clients to understand their specific needs, including size, shape, material, and functionality. Once the design is finalized, the mould is created using specialized machinery and high-quality materials, ensuring that it meets all industry standards. The disposable plastic round food container mould and plastic cup mould are then tested for quality and durability before being used in production.

Why Choose Custom Moulds?

Custom moulds are essential for businesses that require specific designs and functionalities. By choosing custom plastic moulds, businesses can ensure that their products stand out in the market. Whether it is creating a unique shape for a plastic cup mould or designing a disposable plastic round food container mould that meets specific food safety standards, custom moulds offer endless possibilities. These moulds not only improve product quality but also streamline the manufacturing process, helping businesses save time and money.

Custom plastic moulds, such as disposable plastic round food container moulds and plastic cup moulds, are indispensable tools in today's manufacturing landscape. They offer numerous benefits, including design flexibility, improved durability, and cost savings. Whether you are in the foodservice, beverage, or packaging industry, investing in custom moulds can significantly enhance your production process and product quality. If you are looking for tailored solutions to meet your specific needs, custom plastic moulds are the way forward.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français