The Application of Thin Wall Food Container Mould

China Thin Wall Food Container Mould Manufacturer Factory

A thin wall food container mould is a tool used in injection moulding processes to create food containers with thin walls. These containers are used extensively in the food industry for packaging take-out meals, prepared foods, salads, and other items that require efficient, hygienic, and cost-effective packaging solutions. The key characteristic of this mould is its ability to create products with walls that are thinner than traditional containers, reducing material usage and overall weight.

The thin wall food container mould is designed to inject molten plastic into a cavity that shapes the container. As the plastic cools, it forms a solid, durable container with thin walls, which reduces the amount of raw material required and the environmental impact of production. This process makes it an ideal solution for manufacturers looking to balance cost, performance, and sustainability.

The process of creating thin-walled food containers involves several crucial steps. high-quality plastic granules are fed into an injection moulding machine, where they are heated until they become molten. The molten plastic is then injected into the thin wall food container mould, which is designed with specific cavities to form the shape of the container. Due to the thin nature of the walls, the cooling process is accelerated to ensure that the plastic hardens quickly and evenly.

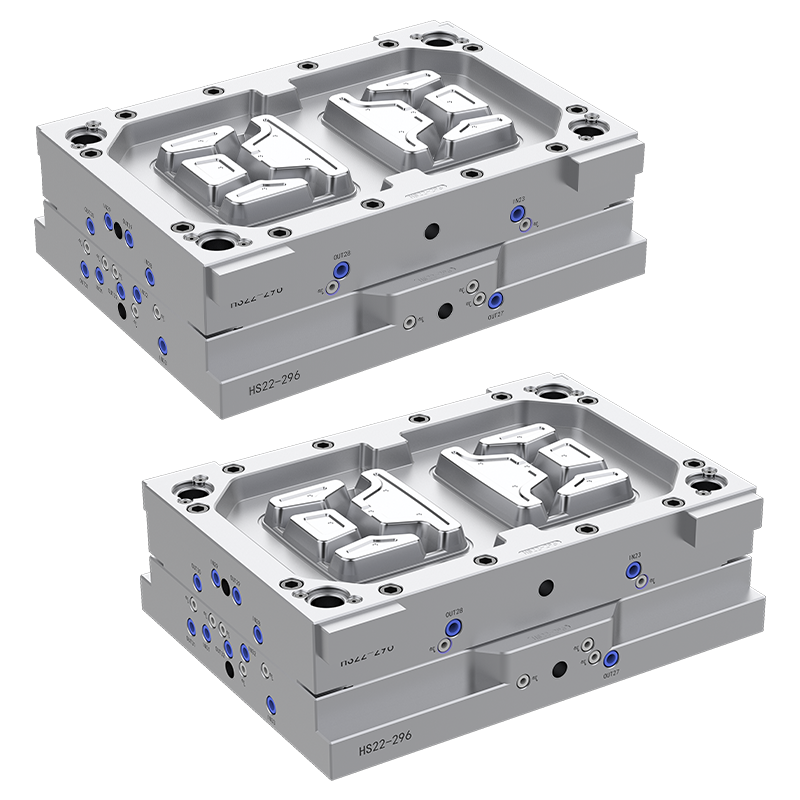

The thin wall food container mould is precision-engineered to maintain uniform wall thickness, as this is essential for ensuring the strength and durability of the final product. The mould may have multiple cavities, allowing for the simultaneous production of several food containers at once. Once the plastic has cooled and solidified, the mould opens, and the newly formed containers are ejected, ready for further processing or packaging.

Material Efficiency: One of the primary benefits of the thin wall food container mould is its ability to produce containers with significantly reduced material usage compared to traditional, thicker-walled packaging. By reducing the amount of plastic required for each container, manufacturers can lower production costs and waste. This is particularly important in industries that aim to reduce their environmental footprint.

Lightweight Design: Thin-walled containers are lighter than their traditional counterparts, making them easier and cheaper to transport. This lightweight nature helps lower shipping costs and energy consumption during transportation, which is an essential factor in today's competitive market where cost-efficiency is critical.

Faster Production Times: The design of the thin wall food container mould allows for faster cooling and shorter cycle times in the injection moulding process. This increased efficiency results in higher production rates and lower per-unit costs, allowing manufacturers to meet the high demand for food packaging.

Durability and Strength: Despite the reduced material thickness, containers produced with a thin wall food container mould retain a high degree of strength and durability. The advanced moulding process ensures that the containers are capable of withstanding typical stress and handling during distribution and use, all while maintaining a lightweight design.

Enhanced Aesthetic Appeal: Thin-walled containers are often more visually appealing than thicker alternatives, offering a sleeker and more modern look. This aesthetic advantage is important in food packaging, as consumers often prefer packaging that reflects the freshness and quality of the food inside.

Sustainability: In today's environmentally conscious world, sustainability is a key concern for both manufacturers and consumers. The thin wall food container mould contributes to sustainability efforts by reducing plastic consumption and the overall weight of packaging. Furthermore, the lightweight nature of the containers helps reduce the carbon footprint associated with transportation.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français