Reducing Costs with the Right Disposable Plastic Multi-Grid Food Container Moulds

The right moulds, coupled with a reliable plastic injection mould supplier, can significantly decrease material waste, production time, and overall manufacturing costs. In this article, we'll explore how selecting the appropriate moulds can benefit businesses, improve cost efficiency, and help companies stay competitive in the ever-evolving market.

Understanding the Role of Disposable Plastic Multi-Grid Food Container Moulds

Disposable plastic multi-grid food container moulds are used to produce containers that are commonly employed in the foodservice industry for packaging takeout, fast food, and prepackaged meals. These moulds create food containers with multiple compartments, providing a practical solution for organizing different food items. By choosing the right mould design and material, manufacturers can reduce unnecessary waste and streamline the production process, leading to significant cost savings.

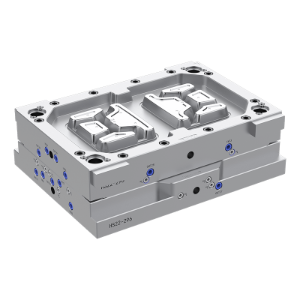

Disposable Plastic Square Four Grid Box And 4+1 Box & Lid Thin Mould

A well-designed disposable plastic multi-grid food container mould ensures that the production process is both efficient and cost-effective. For example, optimally designed moulds reduce the amount of plastic used while maintaining the structural integrity and functionality of the container. This helps minimize material costs and supports sustainability by using less plastic per unit produced.

How the Right Mould Reduces Material Waste

Material waste is a major cost driver in any manufacturing process. In the case of disposable plastic multi-grid food container moulds, improperly designed moulds can lead to excess plastic being injected into the mould, creating unnecessary waste. Poorly calibrated moulds may also lead to defects in the finished product, requiring costly rework or scrapping.

By working closely with an experienced plastic injection mould supplier, manufacturers can choose mould designs that use the precise amount of plastic required for each container. Advanced moulding techniques, such as using the latest injection moulding technologies, can ensure that the plastic is injected with greater accuracy, reducing overfill and ensuring that every part of the mould is used efficiently. This can reduce material consumption by up to 30% or more, significantly cutting down production costs over time.

Shortening Production Cycles with Efficient Mould Design

The speed of the production process also plays a critical role in determining manufacturing costs. With faster production times, manufacturers can increase throughput, producing more units in less time. This leads to a reduction in per-unit costs and increases overall efficiency.

The right disposable plastic multi-grid food container mould can significantly shorten cycle times. For example, moulds that are easier to eject or that require fewer heating and cooling cycles can help speed up the manufacturing process. Furthermore, a good plastic injection mould supplier can provide high-quality, durable moulds that reduce downtime between production runs, ensuring continuous operation with fewer delays. The result is a lower cost per unit, which can help businesses become more competitive in the marketplace.

Selecting the Right Plastic Injection Mould Supplier

Choosing the right plastic injection mould supplier is crucial when it comes to reducing costs. A supplier that understands the intricacies of mould design can help businesses select the most suitable materials, tooling, and production processes that meet both quality and budgetary requirements. Furthermore, an experienced supplier can offer advice on how to streamline the design of disposable plastic multi-grid food container moulds to achieve cost savings without compromising on quality.

Many suppliers now offer custom moulding solutions, allowing businesses to tailor the design of their disposable plastic multi-grid food container moulds to suit specific needs, such as reducing waste or improving production speed. By collaborating closely with a supplier that prioritizes cost-saving strategies, businesses can make better-informed decisions and achieve substantial savings.

Investing in the right disposable plastic multi-grid food container moulds and partnering with a reliable plastic injection mould supplier can provide businesses with significant cost-saving opportunities. From reducing material waste to speeding up production cycles, the right mould can optimize the manufacturing process, allowing businesses to produce high-quality containers at lower costs. As the demand for sustainable, cost-effective solutions continues to grow, businesses that embrace innovative mould designs and work with experienced suppliers will be well-positioned to thrive in the competitive food packaging market.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français