-

design stage

- Demand analysis: Communicate with customers to understand the specific requirements of the product.

- Concept design: Design the preliminary plan of the mold according to the needs.

- Detailed Design: Produce detailed design drawings of the mold, including all dimensions, tolerances and material specifications. -

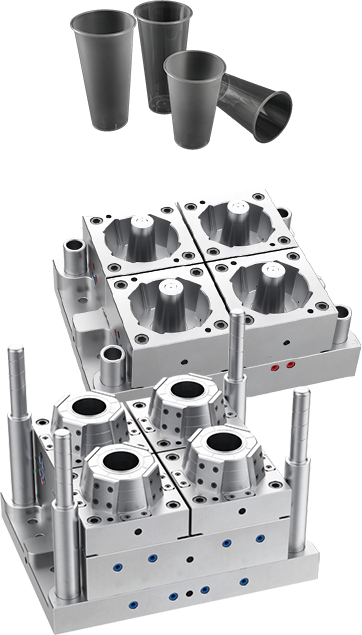

manufacturing stage

- Material preparation: Select the appropriate mold material and prepare it before processing.

- Processing and manufacturing: Use CNC machine tools, EDM, wire cutting and other equipment to process mold parts.

- Component manufacturing: manufacturing all parts of the mold, including cavity, core, slider, ejector pin, etc. -

Assembly and commissioning phase

- Mold assembly: Assemble the processed mold parts into a complete mold.

- Debugging: Debugging the mold to ensure it can work properly and meet production requirements.

- Trial mold: Conduct a trial mold run to produce a small quantity of product to verify the performance of the mold. -

Acceptance and delivery stage

- Quality inspection: Strict quality inspection is carried out on the mold to ensure that it meets the design and functional requirements.

- Modification and optimization: Make necessary modifications and optimizations to the mold based on the mold trial results.

- Customer acceptance: The customer accepts the mold and confirms that the mold meets all requirements.

- Delivery and service: After the mold passes acceptance, it will be officially delivered to the customer and follow-up technical support and services will be provided.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français